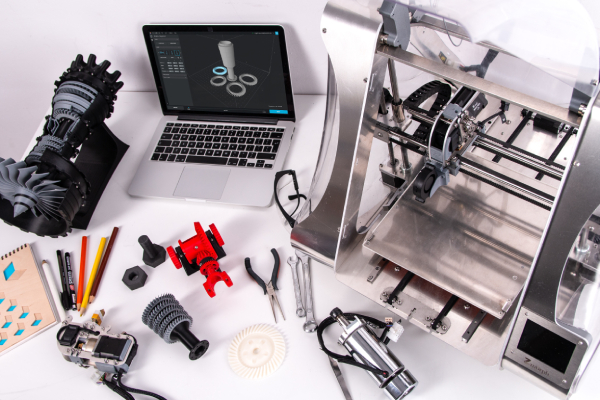

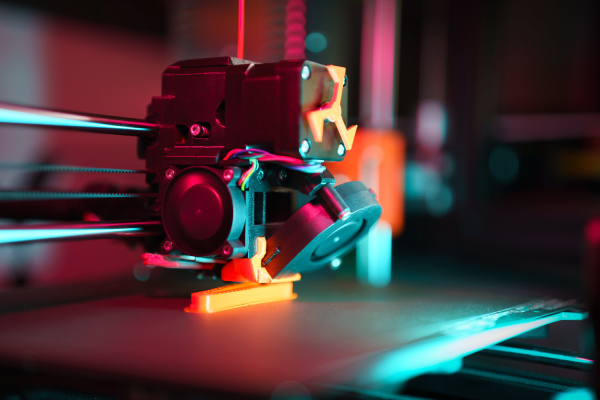

Rapid prototyping, or the fast fabrication of a component, model, or assembly, is not exactly a new technology, but it has emerged as a transformative force in bringing ideas to life. Enabled by the development of 3D printing in the late 1980s, rapid prototyping empowered innovators to swiftly transform digital concepts into tangible prototypes. To this day, it continues to revolutionise the way products are developed by allowing designers and engineers to iterate quickly, detect flaws early, and communicate more effectively with stakeholders.

Are you perhaps considering using rapid prototyping techniques and technology to streamline your production processes? You can partner with reliable product design Los Angeles companies that make use of rapid prototyping and bring your models to life while keeping costs at a minimum. Partnering with such a company or even simply integrating rapid prototyping in your product design and manufacturing process can make the following benefits more accessible to your business.

Accelerated Design Iterations

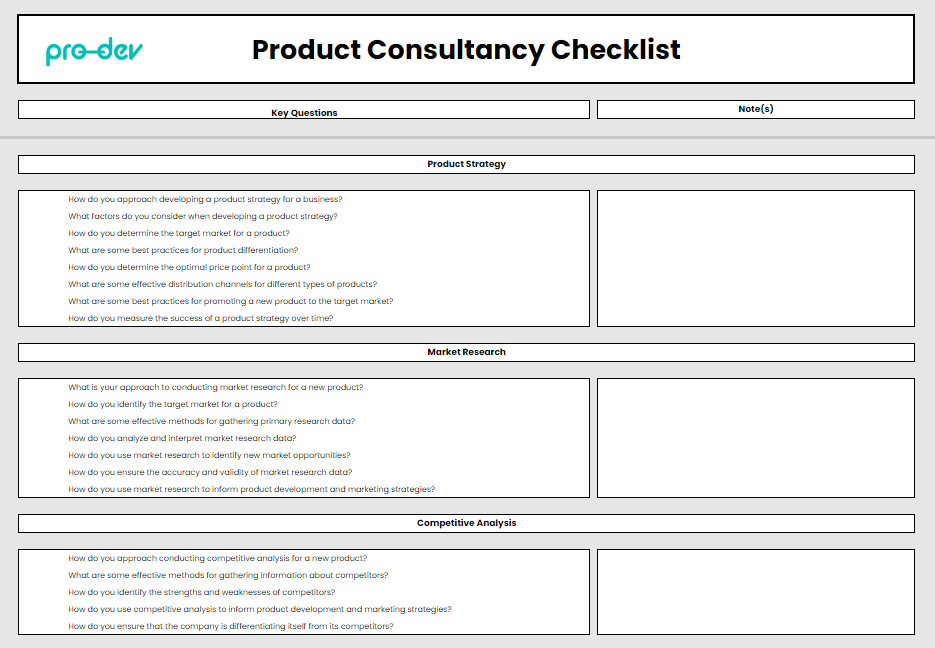

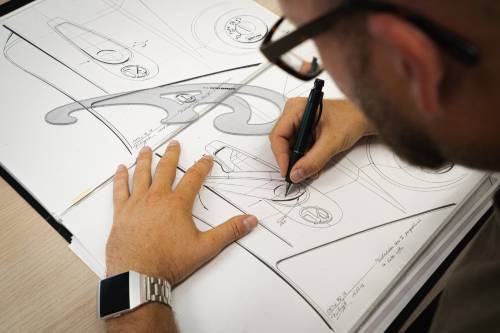

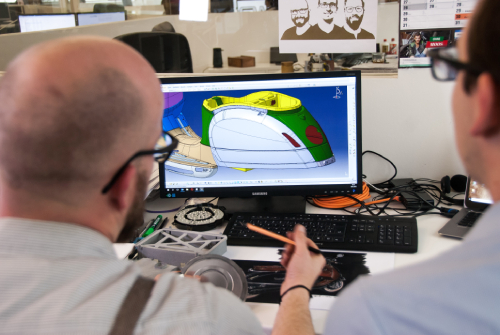

Rapid prototyping enables your business to swiftly transform digital concepts into tangible prototypes. Speeding up this process allows designers to experiment with various ideas in a fraction of the time it would take with traditional methods.

The assistance of a rapid prototyping device, for instance, can empower a design team working on a new consumer product to 3D print multiple prototypes overnight. This, in turn, makes it possible to test different shapes, sizes, and functionalities immediately. This level of agility encourages creativity while ensuring that the final product is a refined version that meets both design and functional requirements.

Cost-Efficient Development

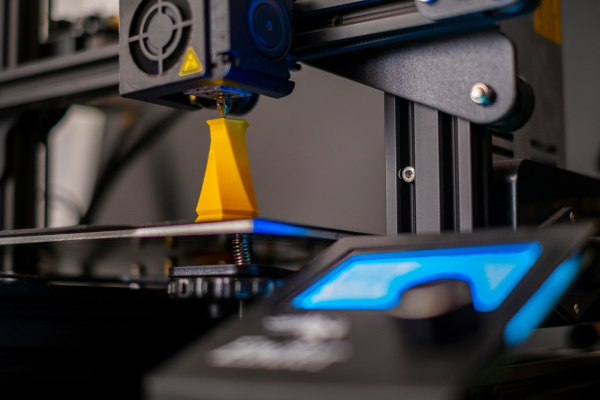

The cost-efficiency of rapid prototyping is particularly beneficial for small businesses or startups with limited resources. Unlike traditional prototyping, which often involves expensive moulds and tooling, rapid prototyping methods like 3D printing eliminate these significant upfront costs.

The use of such technologies, to cite a specific example, empowers a local artisan crafting custom jewellery to create prototypes without investing in costly moulds. This democratisation of prototyping technology makes it accessible to a broader range of innovators and entrepreneurs, which then contributes to fostering a more diverse and dynamic product development landscape.

Improved Collaboration and Communication

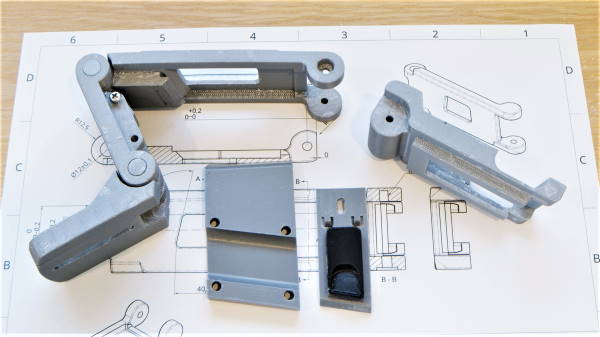

Rapid prototypes are tangible models that serve as powerful communication tools. The physicality they bring to the table contributes to enhancing collaboration among design teams, engineers, and stakeholders. Imagine a team developing a new medical device. The presence of a physical prototype built to scale allows not only engineers but also medical professionals and investors to interact with the product.

This tactile representation fosters clearer communication between all stakeholders, aligning their stance on the product’s design elements and functionality. In this sense, the use of rapid prototypes bridges the gap between technical and non-technical team members and ensures that everyone shares a unified vision for the product.

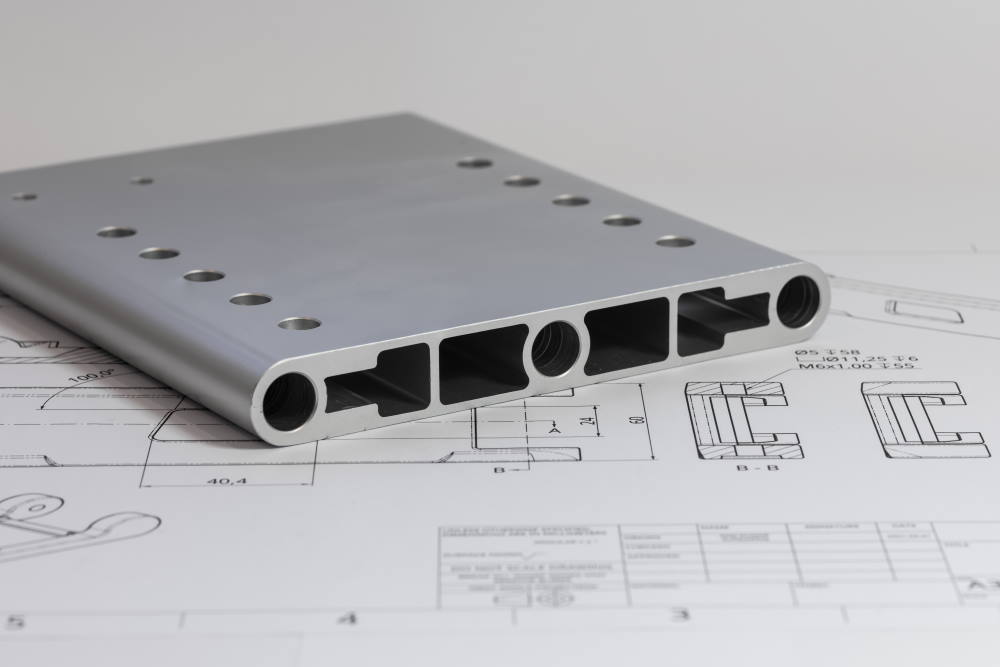

Early Detection of Design Flaws

Rapid prototyping plays a pivotal role in minimising the risk of design flaws reaching the production stage. By creating physical prototypes early in the design process, designers can conduct thorough testing to identify potential issues and take steps to address them. Consider the case of an automotive manufacturer that has the option to 3D print a prototype of a new car part.

The prototype, then, can be utilised to evaluate the product’s performance under stress conditions. This early detection allows for necessary adjustments and reduces the likelihood of costly design errors. Thus, by integrating rapid prototyping into their design process, businesses can ascertain that the final product meets quality standards and customer expectations.

Customisation and Personalisation Opportunities

Rapid prototyping methods offer unparalleled flexibility by enabling the customisation and personalisation of products in a quick and cost-effective manner. When used by a shoe designer, for example, 3D printers can create customised insoles tailored to individual foot contours. This level of personalisation allows the business to meet specific customer requirements as well as open new avenues for niche markets.

The use of rapid prototyping techniques makes it possible for businesses to explore and cater to unique customer needs. This enhances customer satisfaction and creates a competitive advantage for the enterprise in markets driven by individual preferences.

Streamlined Product Development Process

The elimination of time-consuming tooling processes can streamline the entire product development phase. This streamlined workflow is exemplified in the technology sector, where companies can rapidly prototype electronic components using additive manufacturing. The level of efficiency afforded by rapid prototyping ensures that products reach the market faster, which is a time-tested strategy for staying ahead of competitors and addressing consumer demands promptly.

As you navigate the possibilities of product design and development, it’s important to determine whether or not rapid prototyping aligns with your needs. Consider the scale of your project, the need for quick iterations, and the level of customisation that your business requires.

For small businesses, embracing rapid prototyping can lead to cost-effective development and enhanced market competitiveness. Individual creators exploring personal projects, meanwhile, can benefit from the flexibility and efficiency offered by rapid prototyping technologies.

By understanding the unique advantages of rapid prototyping and assessing its compatibility with your specific objectives, you can confidently explore innovations that are designed to bring your ideas to fruition.