Bringing your vision for an original product to reality is undoubtedly one of many business owners' biggest hurdles. For any successful business, you need to launch a unique product capable of attracting many customers. However, bringing a new product to the market can be challenging and cause panic attacks for many aspiring entrepreneurs. Whether you want to find a product manufacturing supplier or connect to a product manufacturer, talking to an expert business advisor is key to getting started.

Developing a design for manufactured products may seem meaningless if you don't know how to produce them. However, you must clearly understand your budget and business requirements to bring your products to market.

Suppose you are an aspiring entrepreneur and find it difficult to turn your ideas and prototypes into tangible products. You can take help from reliable product and industrial design consultancies such as Pro-Dev. Pro-Dev can help you, especially when you want your products in bulk.

3 Phases of Product Development Process

The manufacturing and design engineering process of a product is quite complex. It requires attention to detail and commitment to following each stage. So, do you want to know how manufacturing factories make your products?

To help you understand the product development process, the essential phases that product development companies follow are:

Design Phase

Many aspiring entrepreneurs often get stuck in the first phase to generate ideas for their products. It happens because they are waiting for a stroke of genius to reveal the perfect product they need to sell.

Suppose you are also having difficulty coming up with unique ideas for developing your product. In that case, many products and industrial design consultancies can help you build something unique and creatively fulfilling.

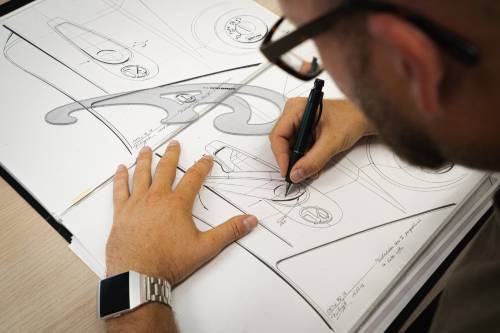

First of all, these product design consultancies will arrange a meeting with you to understand your product requirements.

They will start by asking simple questions such as, "What is your product?", "What is its use?", "What is the target audience for your product?"

Answering all these simple questions will help create a rough image of the product in their minds. They'll start preparing sketches to present concepts they've come up with once they've grasped all of the requirements for your project.

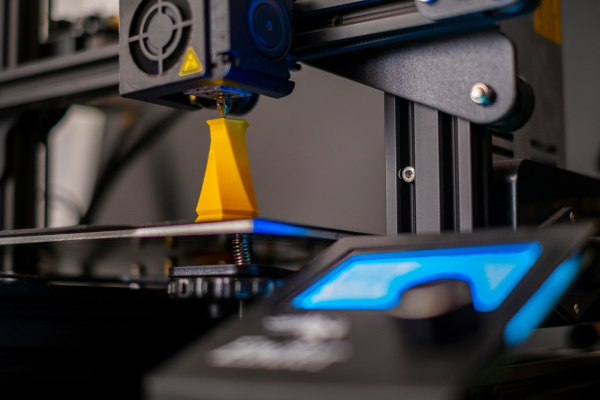

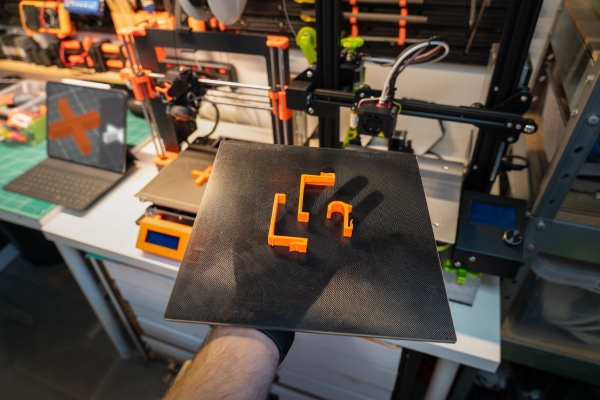

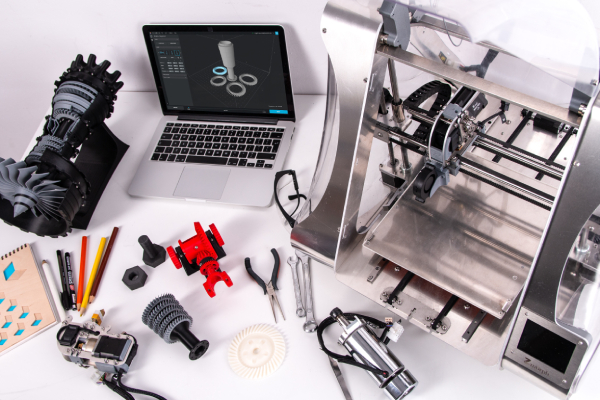

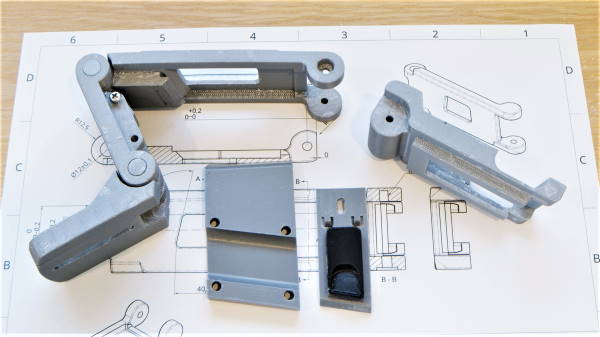

Once you approve the sketches, they will start preparing 3D-printed designs and prototypes of your product. The primary purpose of these prototypes is to create a finished product that mass production can use as a sample.

The prototype manufacturing process is complex, and it isn't easy to get your desired product sample in a single attempt. Therefore, the prototyping phase will involve experimenting with several options and making improvements until you're satisfied.

Engineering Phase

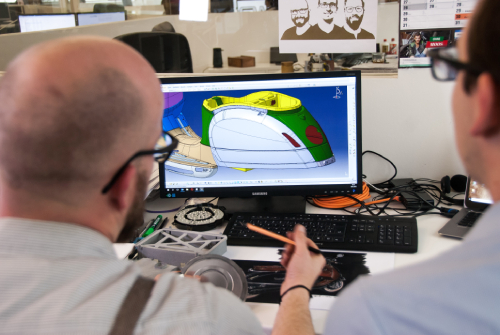

Once you have completed the design work, you need to detail the procedure. Here, the design engineer is responsible for engineering the individual parts to assemble your finished product.

It is time to work on the product's manufacturing process once the prototype testing shows no problems. There might be some significant decisions in this phase, such as raw materials, batch numbers, etc. It is essential to keep costs in mind and remember that using inferior-quality materials will affect your sales in the future.

It is undoubtedly the most critical phase of the product manufacturing process. Any mistakes in this phase will cost you a massive amount of money as you will make all the moulds and essential manufacturing tools with errors.

Production Phase

The product development phase involves the actual production of the product. First, you will have to conduct several tests on the product's prototype. You will decide if you want a large-scale production or not based on the test results.

The production process phase is divided into two parts:

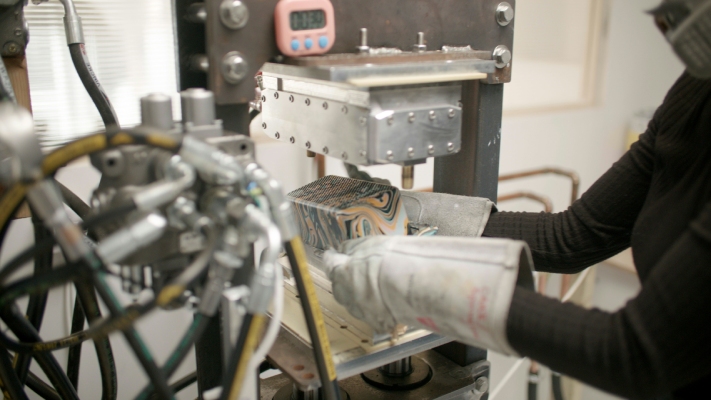

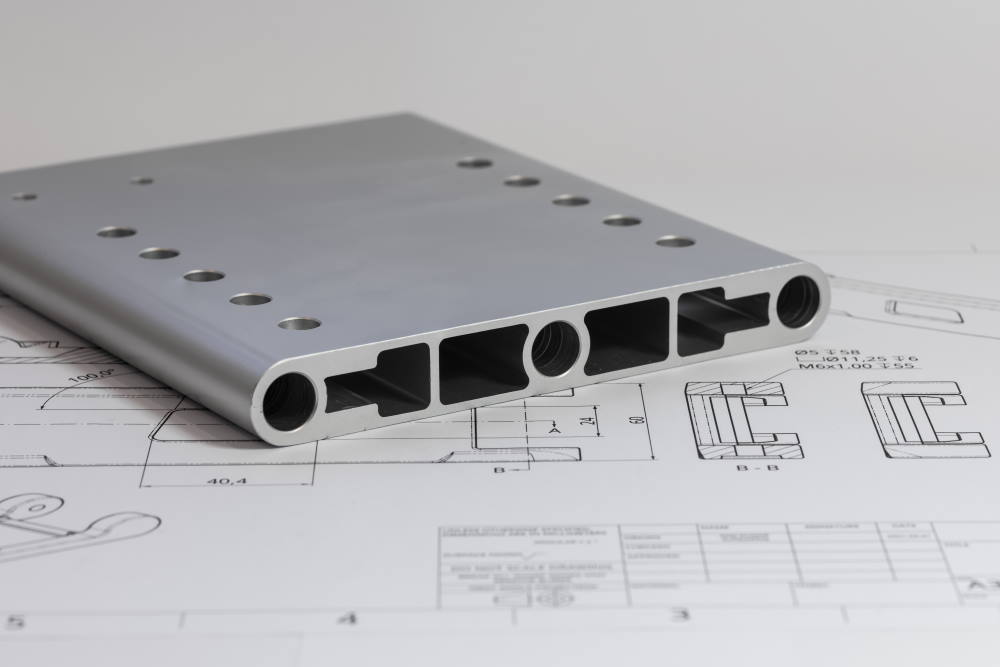

Tooling

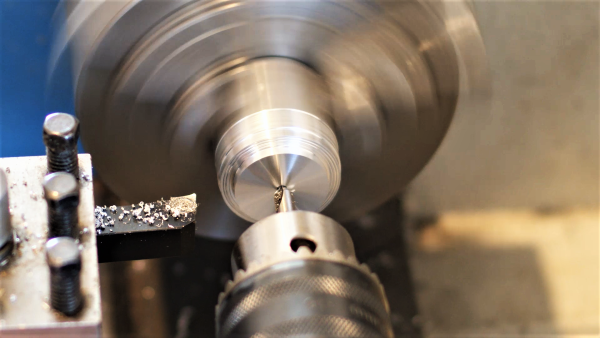

It is the first part of the production phase, which usually takes 30 to 70 days, depending on the process. It refers to building different components and machinery needed for production, like moulds, patterns, and fixtures.

An effective tooling process will ensure the longevity of a product and higher quality control of the product overall. The product development company will further check the first-off tool parts and adjust to refine the finish and fit.

Besides testing tooling parts, a product development company needs to finalize the packaging design of the finished product with clients. The packaging design usually involves the selection of cartoons, labels, stickers, and taglines.

Mass manufacturing

After taking all the necessary steps, it is time to manufacture the products in bulk. It needs a significant amount of investment, equipment, and labour to produce reliable products repeatedly.

Companies producing products in large-scale, use mass-production techniques to avoid highly-priced products and meet market demand expectations. However, this type of production needs heavy investment and equipment.

Now you have successfully taken your product from concept to finished product. It is time to turn your attention to the assembling and packaging of the product. It is worth remembering that customers always seek custom products that are nicely delivered, assembled, and packaged. So, it is necessary not to take the final step of product development, assembling, and packaging the finished product for granted.

Conclusion

Developing high-quality products when starting a business or brand might seem a daunting task. Having the right product design consultancy, such as Pro-Dev, at your side can help you with this. It will be easy for you to go through the entire product development process without worrying about anything. Our company has 80 years of combined experience in product manufacturing and design engineering process.

We have an extensive network of Chinese manufacturers, and we can be your potential manufacturer and help you manufacture your products at a reasonable cost without compromising quality. So, if you are looking for a manufacturing company to prepare high-quality products for your company or brand, contact us. We will help you manufacture the best quality products for your company or brand that meet all your business requirements.