Every step in the product design process involves detail-oriented expertise combined with efficient project management and today's best methods and software platforms. Every client receives customised attention and a unique solution specific to their needs and interests. This simplified design production process will help you understand what product designers do and how they consistently deliver excellence by the deadline.

If you’re looking for expert support in creating valuable, well-designed products, explore our product design services in NZ to see how we can help bring your idea to life.

Product design companies operate in different ways. Here at Pro-Dev, we have perfected our creative process with an eye toward complete transparency, easy collaboration, and top results. One of the significant benefits of working with Pro-Dev involves full and seamless access to experts to make every part of the design, production, and delivery process simple.

No matter what industry or niche you represent, or your specific needs for the end product or part, you understand the benefits of working with a product team that can deliver one-stop solutions from start to finish. We handle the three main steps in the design production process for you without headaches, delays, or surprises. Best of all, we do it all to the most exacting standards with every single order, no matter the size of a cost or client.

Outlining Product and Industrial Design Details

Every design phase and development project begins with a conversation. Multiple conversations occur between clients, the design and development teams, and other essential players in the overall process. The initial meetings with the client involve an in-depth look at their goals and the primary purpose behind the design and development of the product. It is never enough to talk about dimensions, materials, and aesthetic characteristics.

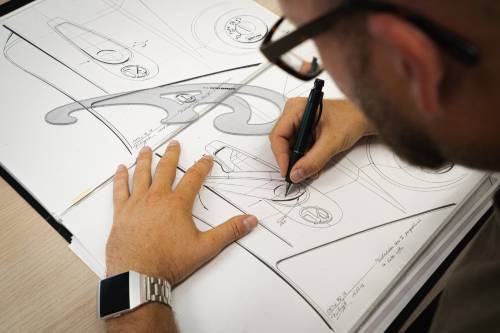

At the core of the product designer's process lies focusing on purpose and fulfilling a need. Once the need is understood, and a preliminary sketch is created, a designer builds the product design into tangible reality. Designers may use any number of tools in the process based on their skills and methodologies. However, the intention behind every step in the process remains focused on the needs of the client and the end-user of the item itself.

The product in question may be anything from a commercial item intended for direct sale or a part of something essential for industrial applications. Before any other part of the process begins, the client and team need to sign off on a clear and specific plan that makes it possible to deliver the best design possible.

Product and Industrial Design Storyboard and CAD

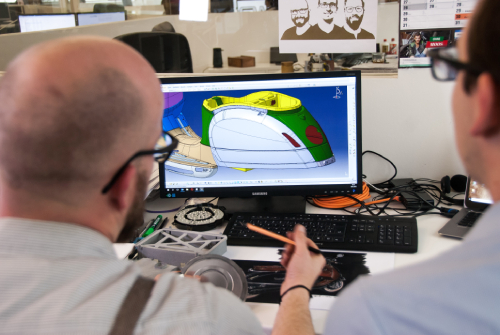

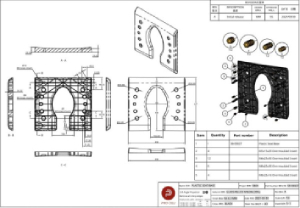

Even with a detailed plan for the product purpose, specifications, and design needs, the next part of the process involves a lot of back-and-forths to approach 100% satisfaction. The designers offer sketches, digital design storyboards, CAD graphics, and mockups in 2D and 3D detail to get a clear picture of what the team provides.

1 – Concept Design and Idea Generation

The first step in the design process involves defining the project, interacting closely with the client, and presenting detailed options to pinpoint the best solution for the client's needs. This process involves a high degree of creativity and practical knowledge that combine together to deliver multiple options for the client to assess their overall plan.

Professional product design firms try not to limit the number of discussions and collaborative meetings during this process. The more information given, the more likely it is that the client is delighted with their successful product in the end.

Project team managers work tirelessly to facilitate interactions to make this process go as smoothly as possible. They provide the most seamless way to communicate with the rest of the team and the client, which involves encouraging a clear understanding of the project goals and tasks.

Part of the responsibility includes building dialogue to help the team communicate even after the client-focused communication is finished. Project managers are the glue that holds the team together and works as a go-between to make every detail of the design project work.

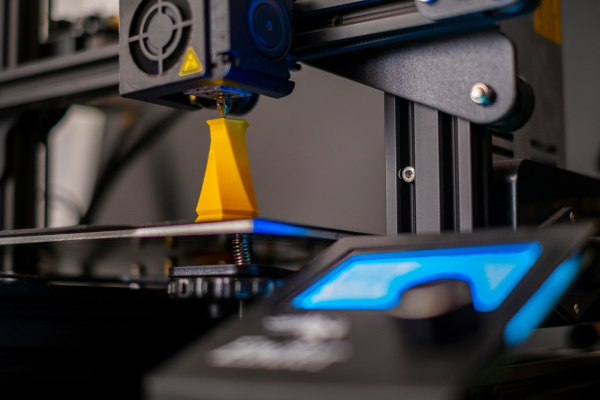

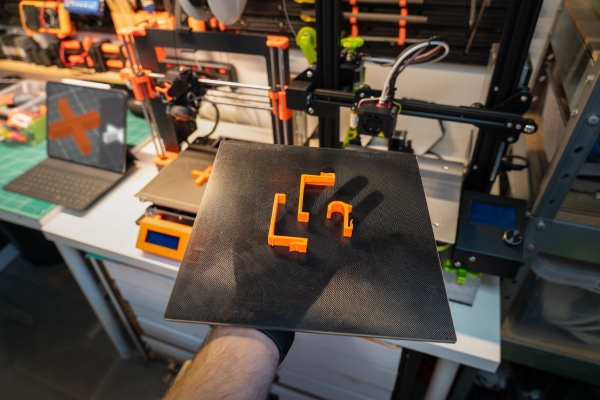

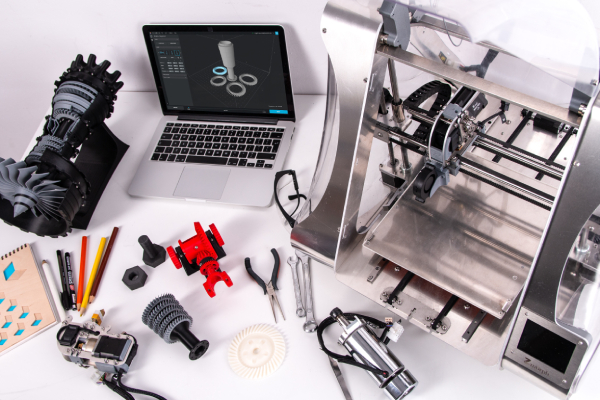

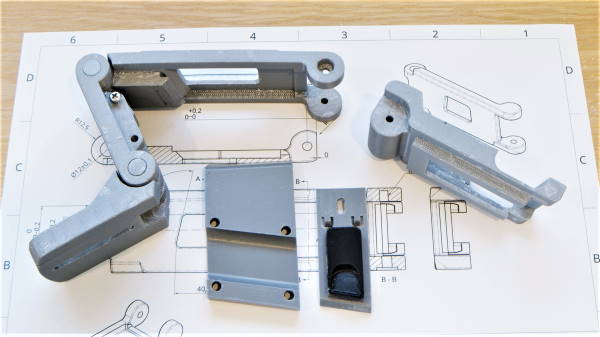

Prototypes and Testing

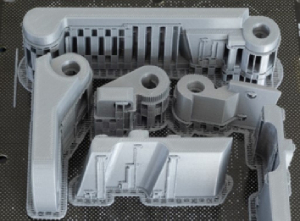

After the team works with the client multiple times with digital representations of what the product will look like in the end, it is time to bring the digital into the physical world. The next step is to create product prototypes and do usability testing to show to the client for approval. The client can then look at them, approve them, and give feedback about what needs to be changed and what needs to stay the same.

The goal is to get input from the client at every stage of the process to make sure they feel satisfied with the final product. It helps to have a 3D, physical object they can hold in their hand to truly get a feel for whether the product serves its purpose.

The creation of prototypes takes place using either 3D printing or other manufacturing processes that suit the specific characteristics of the item itself. This is the last chance for the client to make changes before they lock in the plans and move forward with the product development part of the process.

Final Decisions

What do designers do once the client is entirely satisfied with the design presented to them? One thing they may do is figure out if any improvements can be made to the design. Although most of this is done in the initial planning stage, it is possible that members of the design team noticed something that would benefit the client above and beyond their expectations.

The creativity and experience of designers come into play throughout all the processes mentioned above. None of these would work without the type of exceptional team that operates at Pro-Dev.

They focus on initial concepts and prototyping and hand things over to the engineering and development teams at this stage of the process. At this point, final contracts are signed, and changes will not occur except in particular situations.

2 – Engineering and Product Development

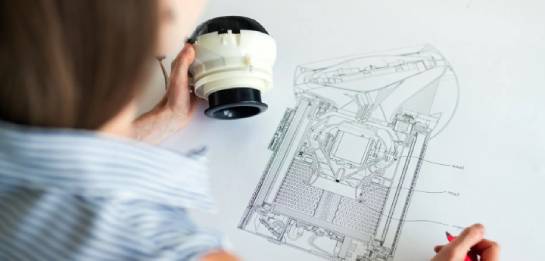

The final plan has been accepted, and client interactions slow down now that the product enters the development phase of the process. Rather than high-concept design details, the team looks at practical matters to make sure parts fit together correctly and work as intended. Precision surpasses all other requirements in this second phase.

This precision of measurements and everything else will lead to a product that works in the end. Every client specification is followed to the utmost accuracy to ensure full compliance with the contract and, more importantly, the buyer's complete satisfaction. The primary focus on solving a problem or meeting a goal with the item only comes to fruition if every detail is watched closely.

Details and Assembly of Individual Components

Multi-part products need unique design processes for each component that goes into making the whole. The product designers hand concepts and schematics over to the engineering team. They are preparing the individual pieces for tooling and formation and ensuring they will all fit together perfectly in the end.

Work With the Factory Rather than the Client

As stated above, the collaboration and communication with the client are primarily over at this stage. Instead, the team interacts more fully with the factory responsible for creating the end products. This ensures the highest level of quality control and accuracy for the first round of manufacturing. Changes can still be made, and the result is delivered to the buyer.

Any error during this phase will result in a lot of wasted time and money if mass production occurs with mistakes included. If the manufacturer makes mistakes in the prototype, there is still an excellent opportunity to fix the problem and move forward.

While this can cause delays, that will not affect the outcome to any significant degree. On the other hand, a mistake in the final production stage means the product cannot go forward until the entire process is rescheduled, more material is sourced and received, and possibly, the contract will be rearranged.

These are the types of mistakes that do not occur at Pro-Dev. We understand how important every step of the product design leading to the development, planning, and production process is. This makes every team member essential to the overall strategy, from the project manager to administrative assistance to CAD designers to intermediaries between the office and international factories. Every person involved with satisfying a client holds to the same degree of excellence.

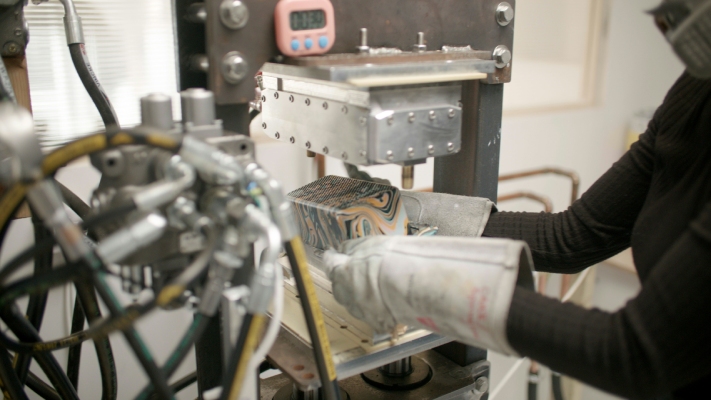

3 – Design Production

The final stage of the product and industrial design and development process involves creating the items themselves. This is when the client can put their plans into action as they will have the product figuratively in their hands in short order. Of course, the tooling and manufacturing steps, depend mainly on the product size, material, complexity, total quantity, and other factors. All this would have been worked out in the initial contract discussions.

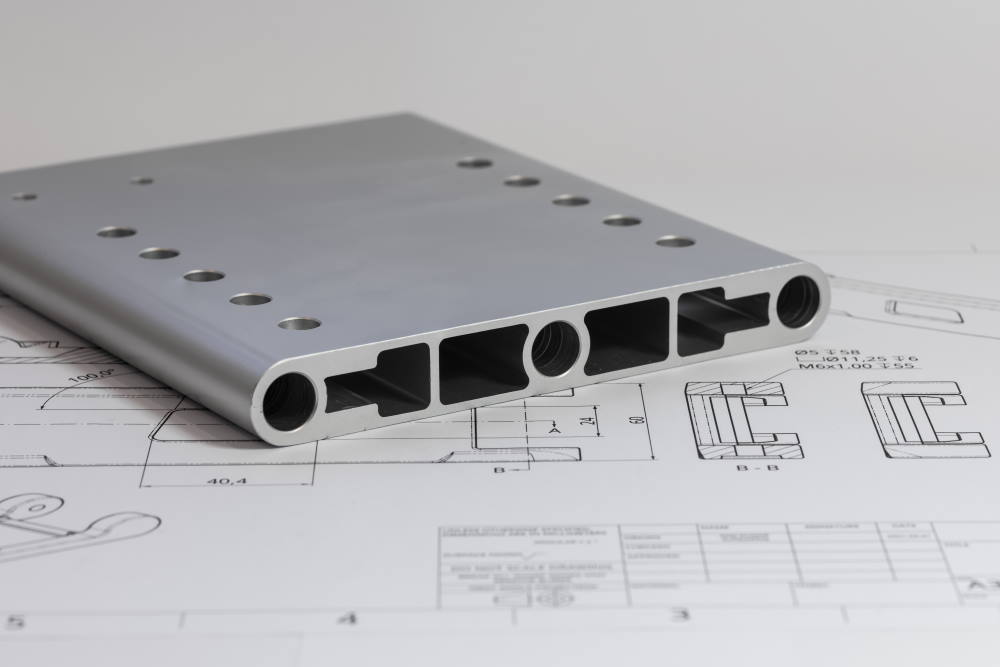

Tooling of Individual Components

Set up for production begins with creating individual components based on their specific material and creation needs. The factories that Pro-Dev partners with can handle many different options for various industries and product types. For example, this step in the creation process can include die-casting, extrusion, injection moulding, and other methods.

Everything is checked and double-checked throughout the entire process to ensure maximum quality and accuracy down to the last detail. Any final adjustments are made at this time. Depending on the design, the number of components, and other factors, this process usually takes thirty and seventy days. The dedicated project team will keep you informed every step of the way and provide complete, timely and transparent communication.

Packaging Design Finalised

Every individual product or collective order of dozens or hundreds of products need adequate packaging for shipment or eventual sale. There are many great tools in the toolbox for creating packaging solutions and many possible directions in the design and implementation of the packaging can go. In accordance with the client's wishes and instructions, the project team works on packaging design and finalises all related decisions. This can include user manuals, pamphlets or other printed material, labels, stickers, cartons and boxes, and more.

Mass Manufacturing

The final stage of the product design and development process has finally arrived after a period of intense collaboration and communication. Double and triple-checking every detail, creating CAD and 3D printed models and functional prototypes, and handling the production process, manufacturing commences.

The approved final product design goes to appropriate factories or manufacturing plants that create individual components and put them together to create the final assembly. Packaging as specified by the client also takes place, and everything is loaded in the final shipping containers for transport to the buyer.

From initial plans and discussions to the final delivery of all manufactured products, the entire process involves a series of steps, conversations, details, and specific situations unique to each client and product. Pro-Dev offers a one-stop solution for all product design and development services. Our strong track record of satisfaction, safety, and efficiency makes us the right choice for your component or complete product design needs.